Several weeks ago I published a short article on choosing a defensive handgun that was, in a tongue and cheek manner, implying shooters need a Glock 19 and on a more serious note a peer handgun of some sort on par with the Glock 19.

In that article, I cast a fairly wide net on the definition of a ‘peer firearm’ and covered a broad selection of 9mm handguns I’d call Service or Duty 9mm’s

Here’s the list by manufacturer. It isn’t an all-inclusive sampling but covers the styles I was talking about.

- Glock: G17, G19

- Sig Sauer: P226, P229, P320, SP2022

- Smith & Wesson: M&P9

- Heckler & Koch: P30, USP9, VP9

- FNH: FNX9, FNS9

- Walther: PPQ

- CZ: 75B, 75BD

- Ruger: American (in theory, very new pistol)

- Springfield Armory: XD, XDG (Mod2), XDM

- Beretta: 92, 92FS, 92G, M9A3, PX4

Rob Pincus, a well-noted shooting instructor, took issue with my article and posted about it on Facebook. I follow Rob, and so does my publisher, so we saw his post about my article.

A discussion ensued and in short, I do not agree with Rob. It’s a simple difference in opinion.

I do see Rob’s point. I listed twenty-four firearms under the monikers Simple, Consistent, and Reliable. I stand by those descriptors, but the firearms are not created equal in those regards, they just fit a baseline minimum, and the rest is buyer preference and comfort.

So let’s break these twenty-four down further into three tiers. Tier 3, Tier 2, and Tier 1 with Tier 1 guns exhibiting the most simplified and streamlined characteristics overall as defensive firearms. Firearms not listed but exhibiting parallel characteristics can be tiered accordingly. This is not intended to nor should it be taken in place of individual shooter comforts and preferences. I would much rather train somebody who brings a Tier 3 gun or any sidearm for that matter, and who shows up ready to learn and grow as a shooter than turn them away because they didn’t bring a Tier 1 gun.

CZ75B

FNX9

H&K USP9

H&K P30

Beretta M9A3 (92, 92FS)

Beretta PX4 Storm

These firearms in their most common commercial variants are Double Action/Single Action (DA/SA) and have manually operated safeties. They also have a decocker feature to safely reset the trigger and hammer forward to the double action position (minus the CZ75B)

While these firearms are well built, reliable, and are often very comfortable for shooters, they are the most mechanically complicated of the listings by having the widest array of possible manipulations.

The DA/SA trigger has two distinct pull weights and reset points. The first pull weight is usually between 9-12lbs with a long trigger travel. After the first shot and slide cycle, the hammer remains set, and the trigger pull weight and travel both significantly decrease. If the shot does not fire the reset for the trigger is all the way at the front of its original travel distance. Shooters choosing a firearm from this tier have to learn both trigger pull weights, resets, and the individual idiosyncrasies of the gun.

Added to that learning requirement, the firearms have manual safety controls. That lever on the weapon that enables and disables the function of the gun adds additional mechanical complication and steepens the learning curve for the firearm. The same lever often acts as the decocker on the firearm as well and steepens the learning curve for the firearm even further. If by sweeping the safety too far the firearm can drop from the expected single action shot into double action that changes what the shooter needs to expect from the firearm while taking their next shot especially if it wasn’t done intentionally.

Military and LEO organizations have often requested and sometimes required this list of features for their service sidearms. This was never due to the designs being simpler or superior and mostly due to the concepts of liability for negligent discharges or a perceived consistency with a different service weapon.

I consider these Tier 3 guns to be fine self-defense firearms should the individual buyer desire to make that choice. However, buyer beware that these are the most complicated end of the spectrum. Buyer’s choice but learning these guns is more challenging and involved, end of discussion.

NOTE: Certain production models of Tier 3’s, especially of the H&K pistols, can be placed in Tier 2 or Tier 1 respectively based on features.

Tier 2

Beretta 92 G (WC Brigadier pictured)

CZ75BD (Also SP01 Tactical variant)

Springfield XDG (XDm, XD)

Sig Sauer SP2022

Sig Sauer P229

Sig Sauer P226 (My personal carry)

FNS9 and M&P9 with manual safeties (not pictured)

With the Tier 2 guns, we move into simpler and smoother mechanical layouts. The lion’s share are DA/SA handguns. The increased simplicity allows shooters to focus on mastering the trigger they’ve chosen and removes the disabling effect of the manual safety. These DA/SA guns will fire when the trigger is pulled, the trigger will transition to single action for subsequent shots. No control (safety) will purposefully or accidently disable the DA/SA trigger system. The accuracy and ability to rapidly deliver follow up shots make these DA/SA systems well-liked choices while maintaining the long deliberate first shot pull of the double action trigger.

These Tier 2 firearms are simpler and in my opinion superior to the Tier 3’s as defensive firearms.

The FNS9 and M&P9 make the Tier 2 list briefly in their manual safety models. The safety is an additional mechanical control but, combined with the simple triggers, the overall mechanical complications are vastly simplified over the Tier 3 list. Shooters add the disabling of the safety on firing and the enabling of the safety on cease-fire to the list manipulations under practice.

Finally the XD models from Springfield Armory. The XD variants do possess all of the qualities of the Tier 1 firearms. I place them in Tier 2 because of personal experience with the design specifically related to the passive safety located on the grip. In shooting competition, admittedly as an amateur competitor, I’ve had the firearm fail to discharge on two occasions on the clock. My grip on my XDm was entirely to blame, the fact remains my shot didn’t go off and in a fight that could be catastrophic. I have never experienced a related or parallel issue with Glock, M&P, or Sig Sauer pistols, and I corrected the issue with practice. But as the possibility is ever present of a poor grip in a bad situation I can’t put the XD series in Tier 1.

Tier 1

FNH FNS9

Smith & Wesson M&P9

Walther PPQ

Sig Sauer P320

Heckler &Koch VP9

GLOCK G19/G17

Ruger American (Honorable Mention, unproven)

Finally, we have the Tier 1 firearms. The mechanical characteristics of the Tier 1’s make them the most simple to use, traits especially useful under stress. They present the shooter the least number of controls and manipulations necessary to gain proficiency on the platform.

What are these characteristics?

No manual safety control is present on these guns. Pulling the trigger will fire them when loaded, and no other control switch is necessary.

Striker fired actions with consistent, repeatable trigger pull allow the shooter to understand and equivocate firing their pistol with one type of trigger pull, not two like my personal preference of firearm the P226. This shortens a shooters learning curve by having one relatively short movement and moderately pressured trigger pull. Even if the weight or travel is altered (new trigger) it will always be the same after that deliberate alteration.

Polymer construction on minimalist chassis designs with generous tolerances for dirt and debris keep the guns running even while fouled up and keep weight down. Machined designs, despite having other advantages, result in higher weight and costs (find a new P226 with a $570.00 price tag, good luck)

These firearms are the top of defensive and fighting pistol design right now, they coalesce around the efficiency of their simple operating concepts. The Glock is arguably the king of the Tier with the longest track history and widest acceptance under some of the harshest testing and longevity in real world use.

While anecdotal, two Glocks we’ve had as rental and training guns lasted well beyond 100,000 rounds before a critical parts failure. The G17 develop a hairline fracture on the slide by the ejection port, and the G19 broke the spring under the takedown tab.

So in conclusion, buy a Glock 19 (yes still tongue and cheek).

Do yourself a favor picking a defensive pistol and invest in your system once you pick it, understand the practice and training realities of the system you are choosing. Pick the firearm you want, but with realistic expectations of how it operates.

And for the love of all things go shoot it. If your investment in your handgun doesn’t include time and ammunition on the range, you’re doing it wrong.

There are two starting points in the production process. Rough forgings arrive here for machining into receivers, bolts, side plates and various other parts. Barrel blanks arrive in the form of large steel bars. Both are drilled, cut, milled, hammered, polished, finished, and assembled into completed rifles, pistols, and machine guns.

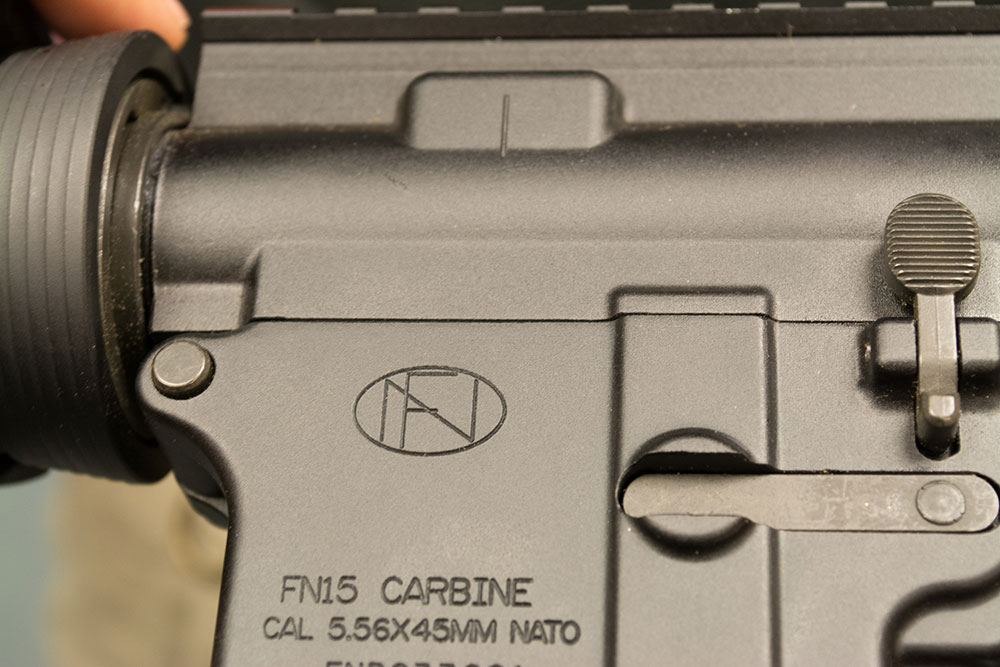

There are two starting points in the production process. Rough forgings arrive here for machining into receivers, bolts, side plates and various other parts. Barrel blanks arrive in the form of large steel bars. Both are drilled, cut, milled, hammered, polished, finished, and assembled into completed rifles, pistols, and machine guns. The CNC machining sections are impressive, but what really captivated me was the barrel shop. I’ve toured a number of factories and seen different takes on the process. What stood out here was the number of steps involved in producing each and every barrel. As a result, FN has become a supplier of barrels to a number of other companies. About the time of our tour, the FN folks were just starting the process of stamping their logo on all barrels supplied to other gun makers, so in the future, you’ll know for sure whether the barrel on your rifle originally came from the FN factory.

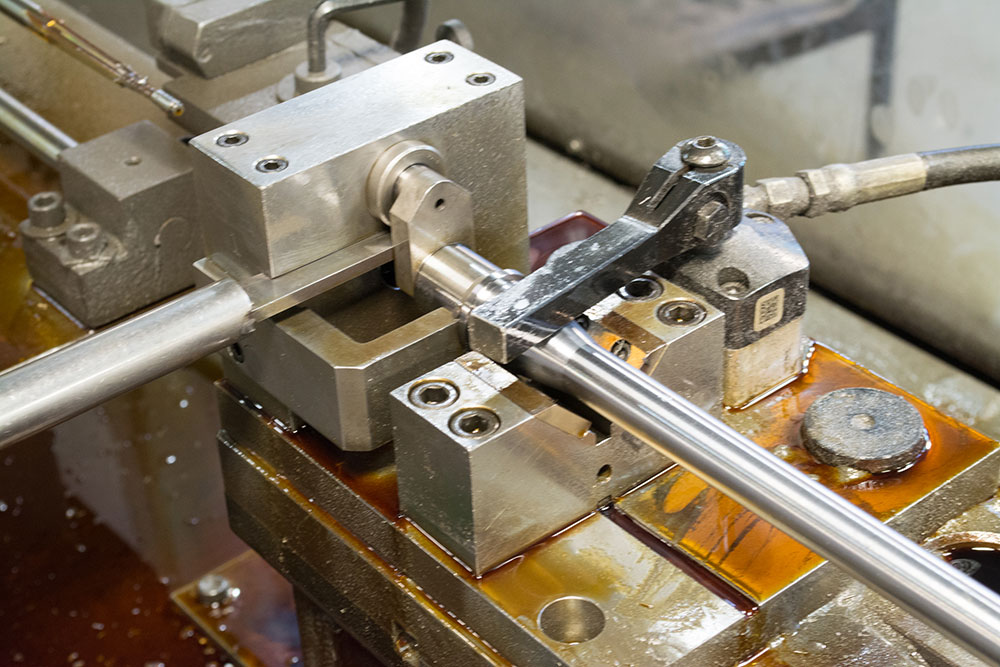

The CNC machining sections are impressive, but what really captivated me was the barrel shop. I’ve toured a number of factories and seen different takes on the process. What stood out here was the number of steps involved in producing each and every barrel. As a result, FN has become a supplier of barrels to a number of other companies. About the time of our tour, the FN folks were just starting the process of stamping their logo on all barrels supplied to other gun makers, so in the future, you’ll know for sure whether the barrel on your rifle originally came from the FN factory. At this stage, barrels face a fork in the road. Military guns with specific contract specifications may head to a button-broaching process. After reaming or honing the interior, a button is pushed through the bore to form rifling grooves. Other barrels, like stainless pistol barrels and those for guns like the FN-15 DMR head down the hammer forging line. First, these barrels are honed or reamed to establish exact diameters and interior finishes. Only then do they go to the hammer forge machines. FN obtains better overall results with stainless barrels, as on their pistol lines, by hammer forging. They’re somewhat unique in that their pistol barrels are hammer forged instead of button-broached or cut.

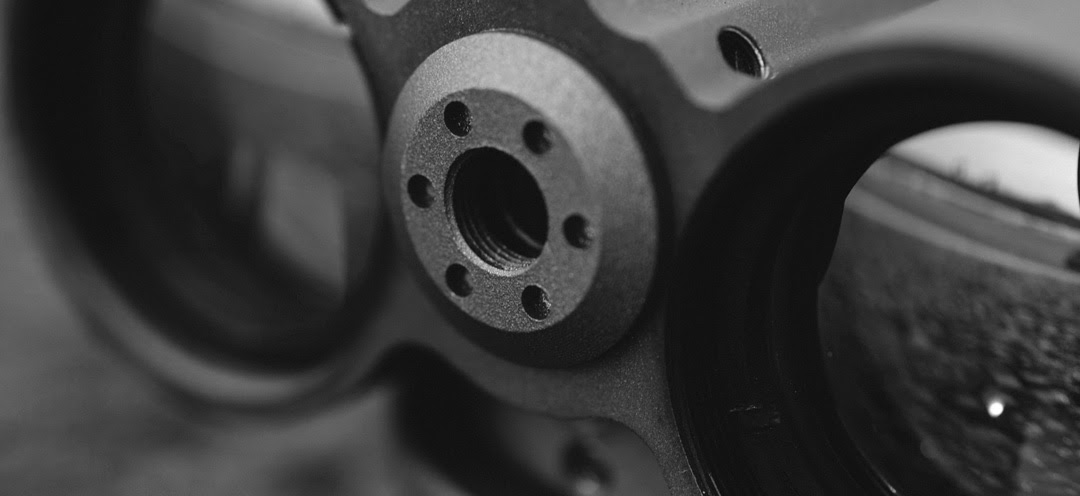

At this stage, barrels face a fork in the road. Military guns with specific contract specifications may head to a button-broaching process. After reaming or honing the interior, a button is pushed through the bore to form rifling grooves. Other barrels, like stainless pistol barrels and those for guns like the FN-15 DMR head down the hammer forging line. First, these barrels are honed or reamed to establish exact diameters and interior finishes. Only then do they go to the hammer forge machines. FN obtains better overall results with stainless barrels, as on their pistol lines, by hammer forging. They’re somewhat unique in that their pistol barrels are hammer forged instead of button-broached or cut. Hammer forging is a miraculous process that makes you appreciate the raw power of modern machinery. The simple explanation is that barrel blanks pounded with incredible force from the outside, thereby pushing the interior of the bore onto a shaping mandrel with an imprint of the desired rifling pattern. The steel literally presses inward to the mandrel and assumes the rifling shape. Ouch.

Hammer forging is a miraculous process that makes you appreciate the raw power of modern machinery. The simple explanation is that barrel blanks pounded with incredible force from the outside, thereby pushing the interior of the bore onto a shaping mandrel with an imprint of the desired rifling pattern. The steel literally presses inward to the mandrel and assumes the rifling shape. Ouch. Rifle barrels also follow a progression of machining and measurement steps from this point on. As in other production areas, operators are responsible for their own quality control before items move onto a second independent quality control step.

Rifle barrels also follow a progression of machining and measurement steps from this point on. As in other production areas, operators are responsible for their own quality control before items move onto a second independent quality control step. Once assembly is complete, every rifle heads to the test range. Yes, every single rifle. Technicians perform live fire tests for both function and accuracy before a gun is certified for delivery.

Once assembly is complete, every rifle heads to the test range. Yes, every single rifle. Technicians perform live fire tests for both function and accuracy before a gun is certified for delivery.

NEW! BIG HORN ARMORY + SILENCERCO® SUMMIT™ PACKAGE

NEW! BIG HORN ARMORY + SILENCERCO® SUMMIT™ PACKAGE

![carllll[1]](http://gatdaily.com/wp-content/uploads/2016/03/carllll1-300x192.jpg)

When I think of modular, the last thing that comes to mind is a holster, until the Eidolon. The Raven Concealment Eidolon might be the most modular holster invented.

When I think of modular, the last thing that comes to mind is a holster, until the Eidolon. The Raven Concealment Eidolon might be the most modular holster invented. The Eidolon’s core-shell is injection molded polymer. It has no rough edges like Kydex that need to be smoothed out. It is designed to accommodate an RMR and suppressor sights while still offering a full-length sweat guard. The sweat guard is something you truly appreciate if you have had any slide work done to increase surface tension. It also accommodates extended slide releases and takedown levers. Which is useful for extended controls, or running a LaserMax Guide Rod Laser. The open bottom allows for use with aftermarket extended or threaded barrels.The biggest advantage of the injection-molded method is in pistol retention. Instead of a Kydex system that creates additional tension on the entire gun retention is tightened at the trigger guard. Once you break free of the trigger guard retention, the remaining draws stroke is smooth as silk without the typical drag of Kydex. It’s like the difference between a clean breaking Geissele trigger and a mushy LC9 trigger.

The Eidolon’s core-shell is injection molded polymer. It has no rough edges like Kydex that need to be smoothed out. It is designed to accommodate an RMR and suppressor sights while still offering a full-length sweat guard. The sweat guard is something you truly appreciate if you have had any slide work done to increase surface tension. It also accommodates extended slide releases and takedown levers. Which is useful for extended controls, or running a LaserMax Guide Rod Laser. The open bottom allows for use with aftermarket extended or threaded barrels.The biggest advantage of the injection-molded method is in pistol retention. Instead of a Kydex system that creates additional tension on the entire gun retention is tightened at the trigger guard. Once you break free of the trigger guard retention, the remaining draws stroke is smooth as silk without the typical drag of Kydex. It’s like the difference between a clean breaking Geissele trigger and a mushy LC9 trigger.