Perhaps you’ve heard of Symtac Consulting, the father-son duo made up of Rob and Matt Haught: high priests responsible for preaching the holy gospel of the Gauge.

But this post is not about either of them nor is it about their awesome shotgun clinics they hold throughout the land, I am writing about the one they call “M’Bogo!”

For reference “M’bogo” is the Swahili word for the African Cape Buffalo, one of the meanest and most dangerous beasts to prowl across the African savanna. The African Cape Buffalo is a founding member of that five animal group that makes up world’s most dangerous game. Hunting them requires powerful and dangerous weaponry with the ability to deliver quick follow up shots in case you miss or fail to put it down with the first shot…lest an enraged buffalo charge and maul you to death.

With the meaning and origin of M’bogo made clear, let’s talk about Matt Haught’s M’bogo.

Advertisement — Continue Reading Below

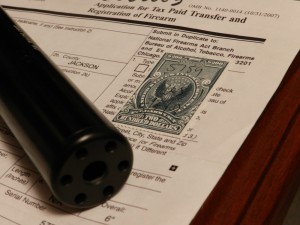

As currently configured, M’Bogo is a fourteen inch short barreled 12 gauge Remington 870 pump action shotgun. Its soul lies in its barrel—one that was fully done up by the gunsmiths at Vang Comp Systems. Not only was this barrel modified by cutting down a longer barrel to fourteen inches and given the internal treatment that Vang Comp is known for, but it also sports a very cool vent rib customization with an even cooler rear safari style sight module.

M’Bogo is equipped with two rear sights, one express style safari sight that is lighting fast when lined up with the front XS front sight via its wide U-notch and its other rear sight, a leaf sight cut into a semi aperture, flips up into place for use with slugs—specifically Federal Tru-Ball slugs zeroed at fifty yards.

Originally, Matt was planning on installing a pistol sight on the front with a folding rear sight. After consulting with GT, the head gunsmith at Vang Comp, GT devised a more elegant solution utilizing the safari style sight module with dual rear sights. It was the implementation of this safari style sight system by GT that inspired the name M’Bogo on this Remington 870 SBS build.

Advertisement — Continue Reading Below

After talking with him, Matt explained how the process of lengthening the forcing cone and backboring the barrel help shotguns maintain very tight and consistent shot patterns. He adds that this is in part because the treatment effectively smooths out the internal bearing surfaces of the shotgun barrel that make contact with the cartridge’s wad and shot column.

Advertisement — Continue Reading Below

Shotgun barrels have a transitional space between their chambers and actual bores known as the forcing cone; the internal diameter in forcing cones somewhat constricts forward of the chamber as it turns into the bore. Many mass produced shotgun barrels have a relatively short length and abrupt constriction—factors which lead to shot being deformed and disturbed as it travels down the bore. Vang Comp’s treatment mitigates this issue and as result, the shot and wad travel down the barrel while being minimally disturbed. Upon exiting the muzzle, the treatment sets up the wad and shot column for success by ensuring very consistent and tight patterns at longer distances than what a normal, out of the box, mass produced shotgun can typically deliver.

Another well known and popular modification that Vang Comp does to barrels is that they port their shotgun barrels. Ported barrels typically have slots or holes around the 11 o’clock and 1 o’clock positions, right behind the muzzle, that allow expanding gases to escape at those specific positions in order to counteract the natural muzzle rise that is normal during recoil.

Advertisement — Continue Reading Below

However, Matt specifically told me that he declined porting on M’Bogo’s barrel because he felt that it wasn’t contextually appropriate for him. He wished to avoid hot gasses near his hand while cycling the action of a short barreled shotgun. Additionally of mention, there are methods and techniques that any shotgun shooter can use to mitigate shotgun recoil and index their muzzle back to their target more quickly, such as the push-pull technique, which incidentally, the Haughts are known for in the American tactical shotgun world.

The remainder of M’Bogo’s daily outfit consists of a Magpul 870 SGA stock, a Vang Comp +1 tube magazine extension, a Vang Comp Big Dome crossbolt safety, a Vang Comp follower, a GG&G sling mount adapter, a Hogue Overmold fore-end, and last but not least, M’Bogo’s receiver is configured to use Vang Comp’s velcro card side saddles.

Besides the Tru-Ball slugs that it’s zeroed with, M’Bogo’s diet generally consists of 8-Pellet Federal Flite Control (LE133 00) shotshells. Matt keeps four in the tube in the “cruiser ready” position and three additional LE133 00 shotshells in his sidesaddle in addition to three Tru-Ball slugs. When doing training drills and practice, M’Bogo enjoys Winchester AA birdshot as it is of high quality and greatly reduces ammunition related malfunctions associated with cheaper types of birdshot that can slow down pump action shotguns.

M’Bogo is a shotgun whose every detail has been well reasoned and considered. Every accessory and detail is not there by accident or coincidence. It is also an iterative shotgun that Matt has slowly changed or altered as he gains more knowledge, experience, or insights. I’ve been fortunate to hold M’bogo in my own hands in the past. When you pick it up, you can’t help but to notice how slick its action is and how grippy the Hogue Overmold fore-end is. When you pick it up and mount it to your shoulder and look down its modified vent rib sights, you know that the shot will connect with whatever it is you aim it at. M’bogo’s heft also gives you a feeling of confidence and reassurance.

Heavy is good, heavy is reliable. Or if it doesn’t work, you can always hit them with it.

Advertisement — Continue Reading Below