GLOCK Perfection. The GLOCK is a widely known and trusted gun. It has proven its ability to perform under strenuous circumstances. One of these circumstances are incorrect operator care.

In case you don’t want to read the whole article here is a break down of what to do and what not to do..

Before doing any of this…CLEAR THE GUN.

You will need to pull the trigger to remove the slide…CLEAR THE GUN.

Now that you have CLEARED THE GUN remove the slide, barrel, and recoil spring

[Editor’s Note: For those unfamiliar with the phrase ‘Clear the gun’ (Yes, I do get emails asking. No, those folks should not “know better,” they are asking to learn and should feel welcome to do so of myself or any of my authors) it means that you must assure that the gun is EMPTY of all ammunition. All brass, bullets, powder, and primers should be out and away from the gun before continuing with any maintenance.

When in doubt on a phrase, part name, location, etc. The internet search engine is your friend. We are from the Internet, and we are here to help.]

YES (DO’s)

- Holding the firing pin safety down shake the slide up and down, you should both hear and see the firing pin moving freely in and out of the firing pin hole. If it does not move freely or moves slowly there may be excess lubrication inside the firing pin channel. Strip the gun down. Depending on if it is a type of lubrication that turned sticky you may want to use a type of solvent or CLP to wet it down and then dry. If it is just overly lubricated take a dry cotton swap and dry it out ensuring that you didn’t leave any of the swab.

- Ensure that the breech face and extractor claw are free of any obstructions.

- Ensure that the tip of the firing pin has no debris.

- Ensure that the firing pin safety moves in and out.

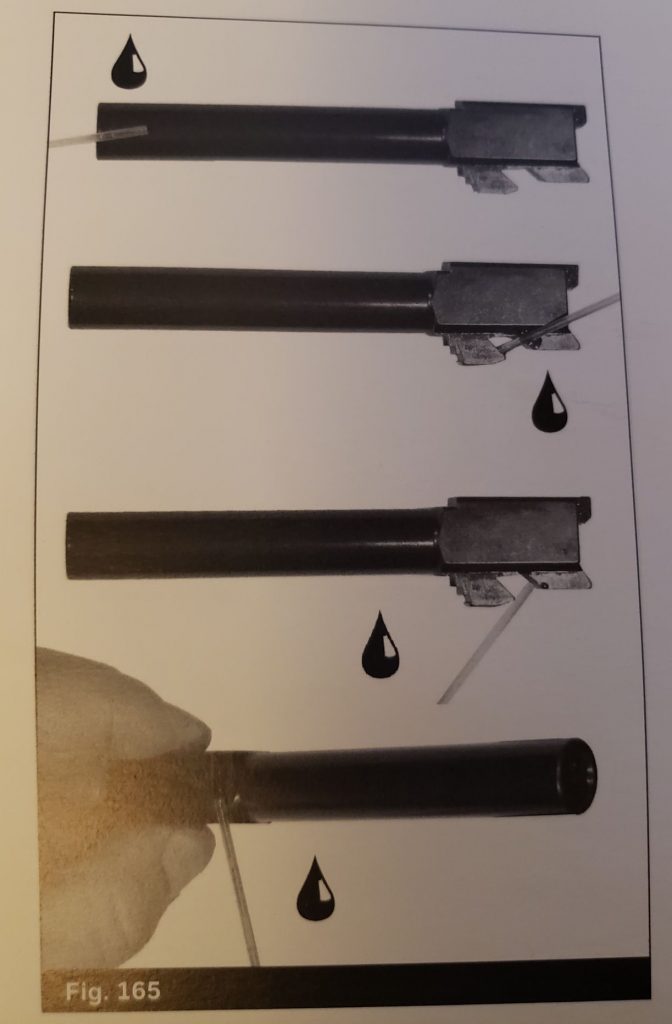

- When lubricating anywhere on a Glock go by the “one drop” rule of thumb. Only use one drop at a time for the place you are lubricating.

- Ensure that the slide stop moves freely up and down.

- Function Check

NO (DO NOT’s)

- Do not put lubrication down the firing pin channel.

- Do not squirt lubrication everywhere on the gun as you would AR type rifles and such..

- Do not put the gun away after using solvent without proper lubrication.

- Do not forget to dry the gun after cleaning with lubrication.

Lubrications

When referencing lube in this article it will mean any lubricants designed for use on firearms. I lean towards CLP (cleaner lubricant preservative) and brands such as G96 or Radcolube. These are all used in the Military as they meet the set specifications. I also like to use a bottle that allows a straw to be inserted. This really helps with applying one drop at a time.

Out of the Box

The first thing that you will notice when unboxing a Glock pistol is a type of coppery grease that is on the rails of the slide. Leave it there. This is a “high-temperature, factory applied lubricant for new pistols. It should be allowed to remain until it naturally wears away to assure long-lubrication of this area.” –Glock Armorers Manual

Before first firing, run a clean patch through the barrel and repeat until clean. Always going with the rifling, as the bullet would travel.

Look for any large residue on the breech face and under the extractor claw. If there is any, you can use a CLP wet brush with the muzzle down to wipe away. Ensuring that none of your lubrication enters the firing pin channel.

Helpful Hint: One thing that is seen that can affect the end users experience when firing their Glock are dry rails. Help the gun out. Put one drop of lubrication on the inside of each rail and let it drip down the entire rail or cycle the gun a few times after assembling. This will also spread the lubrication.

Post Firing Cleaning

Before lubrication and storage, use a dry cotton swap, brush, or pipe cleaner and wipe the caked on carbon off of the slide and frame. Don’t scratch, just wipe. Use dry due to the fact that lubrication is not wanted on every part of the gun that needs cleaning. The only place you may want to lubricate when cleaning is inside the barrel. Run a wet bristled brush through the barrel and then a dry patch.

Now that carbon is removed, lubricate.

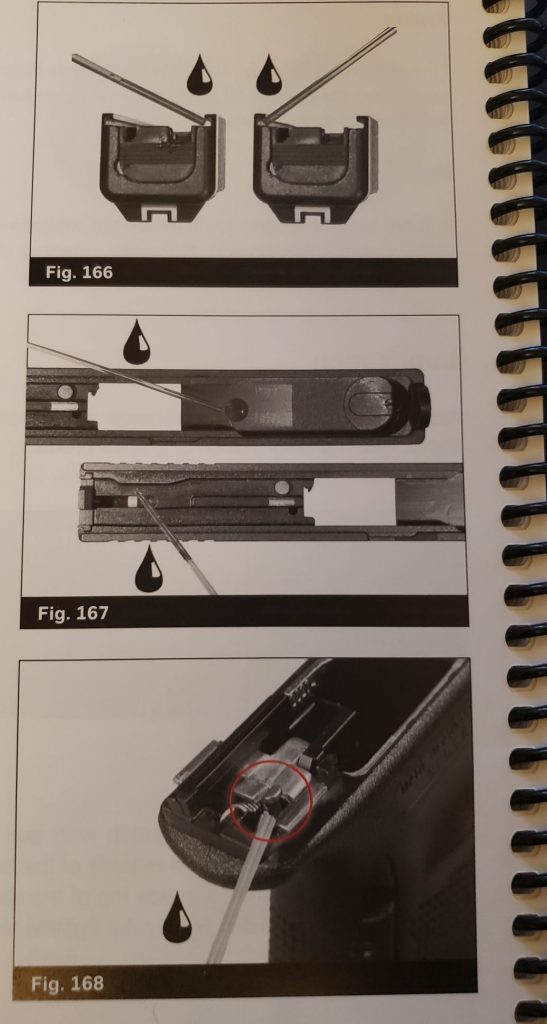

Where to Lubricate..One Drop Method

- the outside of the barrel, barrel hood and lugs, and the ridge where the barrel hood rubs against the slide

- entire length of slide cut rails

- exterior surfaces of the inside of the slide(less is more)

- right rear corner of the frame, where the rear of the trigger bar touches the connecter

These Glocks are life saving devices and meant to run..The one time I have seen them not want to run is when an operator used an improper type of lubrication inside of the firing pin channel thus seizing the firing pin. That is why it is so vital to always check the firing pin for free movement. Less is more with these Glocks. If you are weary of an operator tell them to use dry tools.

From Glock..

https://us.glock.com/en/OWN/Caring-for-your-GLOCK