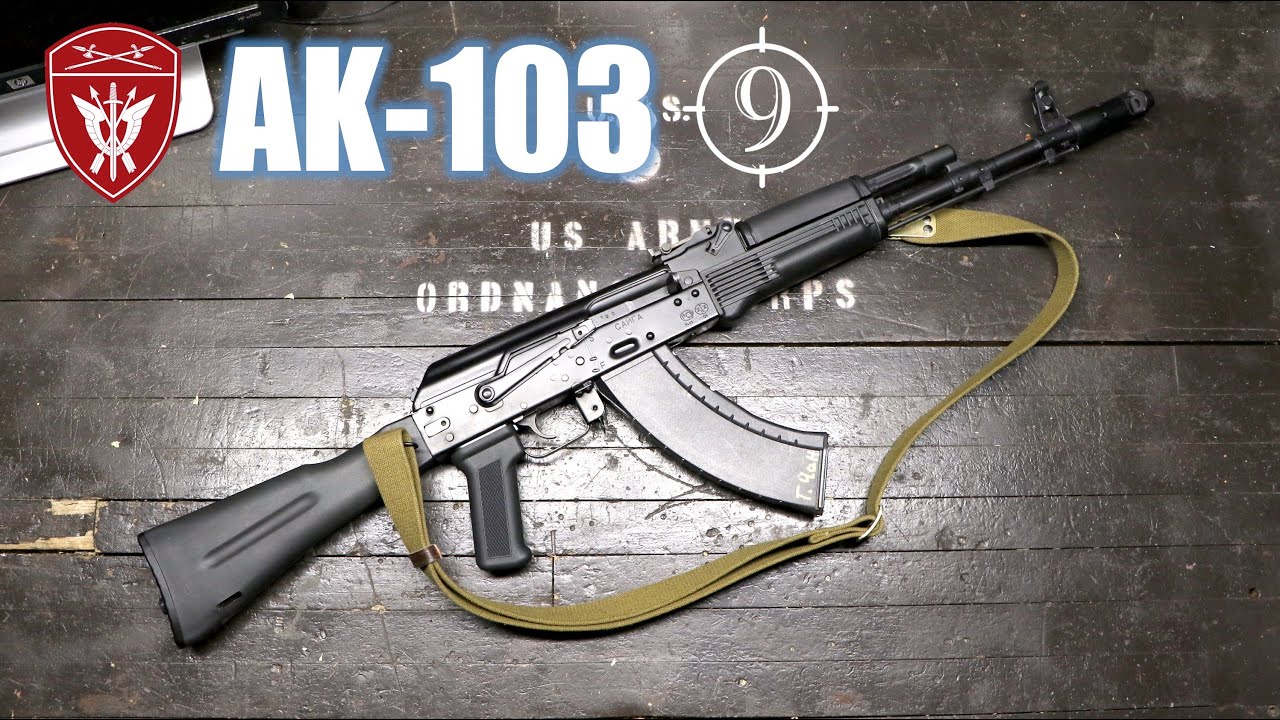

This is one of the most interesting videos yet from 9-Hole Reviews (who are approaching 200k subscribers, so let’s help get them there especially if you aren’t subscribed already) and not because the AK-103 is some legendarily, groundbreakingly, radically new rifle. It wasn’t the rifle itself, it was the process of making it.

The AK-100 series is the fighting rifle meets a giant manufacture/export demand, taking everything they had learned from the original AK-47 through the AK-74M. While not changing the core of what the AK rifles are, as full stroke piston, stamped receiver, forged trunnion construction, the 100 series standardizes as many parts for as many models as feasible.

Meaning that a bare minimum number of parts need to be changed out on a workbench in order to build a different model of the AK-100 series. Barrels, bolt heads, pistons, gas blocks, and sight bases. Receivers, trigger groups, stocks, and the like all stay the same.

Advertisement — Continue Reading Below

The AK-103 is fine example of a simple modernized AK in the same way many companies have come out with very streamlined, simple, functional AR’s. But it’s genius, still helmed by Mikhail Kalashnikov, was in its streamlined manufacturing. It was an ultimate expression of Russian arms exportation to nations needing to run a very simple to make rifle. The rifle could still be easily built for the native ammunition supply of choice too.

As to the 103 itself, the rifle benefits from many of the parallel product improvements that we saw come to M4. They front loaded all the things they had found could make the AK run better or be built quicker and more cost effectively and implemented them all into the whole line. The 103 is like the AR-15 after mid-length gas systems, QPQ nitride, closer tolerance finishing, M4 feed ramps, H1 buffers, and the like all improved the AR incrementally.

It sits as a simple yet modern turn of the century standard for a well storied rifle series. But enough from me, enjoy the video.

Advertisement — Continue Reading Below