Did you know that a Glock only has 34 parts? And that each model is essentially the same gun in different calibers and frame sizes? Glock is the perfect example of the modern firearms industry. As firearm designs advanced, they’ve become more reliable, cheaper, and ultimately more “plug and play” in their nature.

Plug and Play and Firearms

Plug and play firearms, like the AR-15, the Glock, and nearly every other modern gun, have placed a priority on modularity and reliability. Guns have certainly gotten more accurate and more ergonomic, but there seems to be a fundamental focus on making them simple, which is a product of successful mass production.

Advertisement — Continue Reading Below

This fundamental shift allows firearms to be easily repaired, disassembled, and improved. This has seemingly led to both a better firearms industry and a decline in core knowledge of how firearms and ammunition work. This is inevitable. Most of us don’t use the Dewey Decimal system because the internet exists. To me, it’s fascinating, and it’s an idea I wanted to explore.

Namely because I had a Remington 7400, and it’s clear as day how much guns have changed even since its introduction in 1981. I want to illustrate what’s changed in both the gun industry and gun culture, along with the benefits and the downsides.

The Reliability Revolution: Prioritizing Function Over Finesse

When you look at guns like the AR-15, you realize they are designed to run with the best and worst ammunition. You can shove some serious junk in any modern AR, even cheap ones, and it will run. Cheap ones might not run as long, but they’ll go bang.

Advertisement — Continue Reading Below

This is because a lot of AR companies overgas their guns. They use larger gas ports and shorter gas systems to create a rifle that can shoot 77-grain OTM rounds as reliably as Tula 55-grain steel-cased .223. This provides a massive margin of error.

There are some consequences to this design. You get more recoil, more wear on the gun, and a less smooth-shooting rifle. This need for total reliability also means concepts like the Dissipator will never be popular because they don’t have that massive margin of error. There are exceptions, especially when you get into the higher-end rifle market, but guys buying those don’t need plug-and-play guns.

Advertisement — Continue Reading Below

Let’s talk about my Remington 7400. This gun is so ammo-picky that you have to find a “pet load” for it to shoot both accurately and reliably. My .270 Winchester 7400 ran great—with the right ammo. The right ammo for my gun might not be the right ammo for your .270 7400. It’s just the way it was, and people accepted it.

Modern guns also don’t require a break-in period, or at least most don’t. Some semi-auto shotguns tend to require a break-in period, but they tend to be on the cheaper side. People wouldn’t accept a semi-auto handgun with a break-in period in 2025.

Mechanical Simplicity Rules

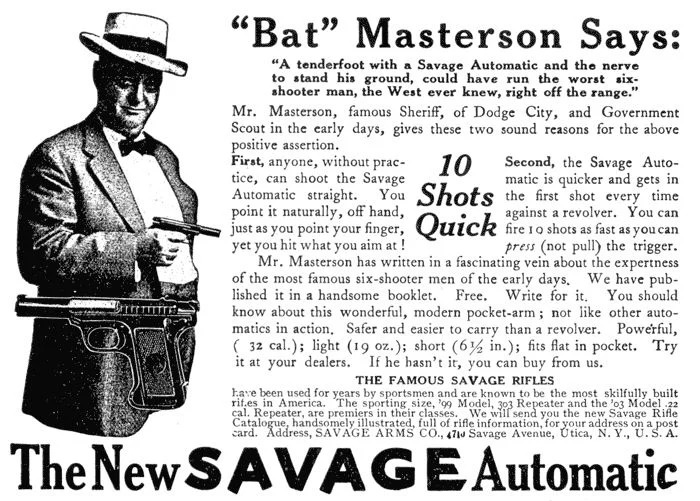

Guns have gotten better by getting simpler. Take apart a Winchester Model 1897 and a Mossberg 500. Which is simpler? Which is easier to disassemble? Better yet, which is easier to reassemble? When Savage released the M1907, it was considered revolutionary because it didn’t use any screws to hold it together.

Advertisement — Continue Reading Below

I’ve mentioned Glock and its 34 parts, but without context, that doesn’t mean much. Let’s look at another 9mm pistol, the old Luger. The Luger has over 120 parts, with some variance depending on the model and time of manufacture. That’s not quite plug and play.

Fewer parts and a simpler design do wonders. It makes the gun easier and cheaper to produce. Fewer parts reduces failure points, which increases reliability. Modern guns are easier to strip and clean. One of the reasons the M50 Reising failed was that Marines would lose the small parts while cleaning the gun in the field.

Advertisement — Continue Reading Below

The rise of polymer in guns has also radically simplified construction, as has modern CNC machining. You can easily make frames and receivers. Heck, 3D printers are building Glocks all the time by 3D printing the frame.

Modularity, Repair, and the Rise of the Builder

Speaking of 3D printers, the ability to build or customize a modern firearm is easy. Simple guns existed, namely guns like the “bullet tube” we called the STEN, but the STEN was a piece of crap. Modern guns aren’t pieces of crap.

The Glock and the AR made firearms that don’t require special fitting for upgrades. You can easily swap parts and pieces and make the gun truly yours. On something like a 1911, you’re likely to require fitting to make a new part fit and to be reliable. This is true on most, if not all, firearms of the 1911 era.

Advertisement — Continue Reading Below

Modern firearm repairs typically consist of swapping a part. If an AR part breaks, you can fix it by yourself. Rarely does a repair require you to send it to a gunsmith or to the factory; if you get to that point, it’s a serious failure. This makes most repairs plug and play.

Democratization of Knowledge

There used to be a time when guns were more like cars. They required someone with specialized knowledge to fix and repair. In the early days of the AR, this was still true. The same goes for most modern guns, until the internet democratized information. Now, I can go on YouTube and figure out how to fix or swap parts with absolute ease, which has contributed to plug and play designs.

Advertisement — Continue Reading Below

The CZ P-09 trigger system is a fair bit more complicated than a Glock’s, but with the internet’s help, I’ve installed a short-reset trigger. The internet has also created a system for direct-to-consumer parts. You don’t have to know a sales rep to order a part; just go to Brownells.

Additionally, forums have made it easier than ever to ask questions. You added a compensator, and your gun doesn’t work? Well, go make a post about it. Your AR is failing to lock back when the last round is fired? Go ask the internet.

Advertisement — Continue Reading Below

Additionally, if a gun doesn’t work, someone will complain about it. Most of the time, that is justified; other times, they bought a Dissipator and are mad it doesn’t cycle steel-cased .223 all that well and label the gun unreliable. Gun companies don’t want that heat, so they stay away from interesting oddballs for the most part.

The Downsides

There are tons and tons of upsides to plug-and-play guns. There aren’t any downsides I can think of when it comes to the guns, but there are some I can think of when it comes to the gun industry and culture. The first is the decline of the gunsmith.

I wouldn’t know how or where to find a local gunsmith. If I did, how many of them could work on older guns that require fitting, or even the construction of custom internal components? Do they just work on Glocks, ARs, and maybe 1911s? Real gunsmiths have become highly specialized, with long wait times and high prices for their rare skills.

Additionally, with the ability to purchase ammo online at any time, in bulk quantities, there are a lot fewer reloaders. With fewer reloaders, we seem to have fewer wildcats and interesting ammunition designs.

That’s partially because there is already a caliber for everything, but also because it’s not as common to see fabricated barrels for random cartridges, and small shops able to produce the parts needed to make oddball calibers like .38/45 Clerke.

Plug and Play – Not Going Anywhere

The plug-and-play nature of guns isn’t going to change. It would be silly to expect anything like that. It’s better for gun owners and the industry, but it’s sad to see the decline of gunsmiths and pet ammunition loads and wildcats. I long for days I never lived in when Guns and Ammo would highlight some random dude in Kentucky making a .222 Whoseitwhaatz cartridge because it was 150 FPS faster than the competition.

I also like spending $500 and getting a handgun that will last longer. That’s the duality of man, I suppose.