Two legends in the outdoors industry, Robert Young Pelton and William W. Harsey, honor a hero, Army Special Forces and CIA Paramilitary Legend Billy Waugh. The Billy Waugh DEMO Knife was born by honoring a Life Behind the Line!

“Which knives did you use, and what do you wish you had?” Robert asked. Billy replied that one of his favorites was an Army-issued stainless steel folding knife called the Demo.

RYP/Harsey

RYP Design is a new venture where Pelton collaborates with designers and legends to create unique products, including books, graphic novels, and knives. He partnered with William W. Harsey, a renowned designer known for his legendary combat knives, including those he created with Colonel Rex Applegate and Chief James Watson.

Advertisement — Continue Reading Below

Notable designs include the Neil Roberts Warrior Knife, dedicated to a fallen soldier, and the Yarborough Knife, presented to U.S. Army Special Forces graduates. With Billy Waugh’s extensive experience, they aim to produce exceptional knives like the DEMO, which embodies the spirit of RYP Design.

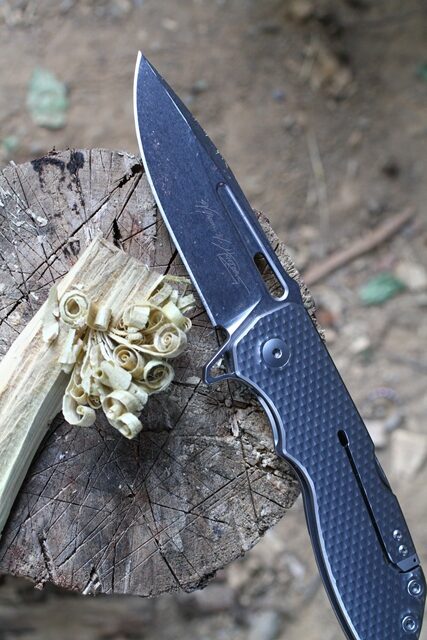

Billy Waugh DEMO Knife

The Billy Waugh DEMO is a robust medium-large EDC knife, measuring just over 9 inches when open. It features a 3.78-inch blade made from Böhler M390 steel, hardened to 60 on the Rockwell scale, and coated with stonewashed matte black PVD.

The handle is crafted from durable diamond-patterned 3D titanium and provides a substantial grip. With the IKBS (Ikoma Korth Bearing System), blade deployment is ultra-smooth and effortless.

Advertisement — Continue Reading Below

Additionally, the knife includes a tungsten carbide glass breaker at the pommel and a replaceable flathead screw. The deep pocket combat clip, engraved with Billy Waugh’s signature, allows for easy, tip-up carry.

Talon Spike

This tool resembles a narwhale more than a typical Swiss Army Knife awl. Made from 440 stainless steel, it features a rounded and smooth design, making it more of a gouger than a driller. It splices rope and untangles knots more effectively as it expands gradually and doesn’t have a sharp edge, instead wedging the cordage without cutting.

Advertisement — Continue Reading Below

The tool stays solid during use, has a wide thumb nick for easy handling, and operates smoothly on bronze washers, delivering powerful punctures.

Deploy It Right

The IKBS enables smooth blade deployment through various methods. While there’s no thumb stud, a recessed area transitions seamlessly into a fuller, allowing for a slow roll pinch opening. Although flicking the blade with the forefinger or middle finger can be quick, it requires practice, and I prefer the flipper. A simple wrist motion combined with pressing down on the flipper makes for rapid deployment, resembling an automatic switchblade.

In reverse mode (tip up), a middle finger flick with a wrist snap opens the blade quickly. The cutout allows for pinch-gripping and wrist flicks, and for a slower approach, you can use one hand to hold the knife while the other utilizes the cutout like a nail nick. Both methods work well for deploying the blade.

Advertisement — Continue Reading Below

Make It Back DEMO Knife

The Billy Waugh DEMO knife exceeded my expectations during rigorous testing. Right out of the box, it easily shaved hair from my arm. For heavier tasks, I tested it on a thick rubber hose, where it sliced through effortlessly.

Deploying the blade was smooth, thanks to well-designed bronze washers and a deep nail nick, allowing easy access even in low light. I tested its puncturing ability on an empty metal MotoMix canister, which it penetrated with ease, and then on a rubber tire, again demonstrating excellent comfort and performance. The sharp spike, which I prefer to call a talon, is a valuable feature of this knife.

Advertisement — Continue Reading Below

During the blade tests, slashing, stabbing, and slicing were evaluated. The blade punctured light metal canisters, demonstrating solid performance. Using an icepick grip and leather gloves, the DEMO easily stabbed through the MotoMix canister, pivoting back and forth. The sharp blade sliced through the second canister just as effortlessly.

Next, the Böhler steel blade was tested on heavy nylon tow strapping, requiring a sawing motion to cut through. Despite the tough job, the handle remained comfortable, and the lock functioned well. Fatwood shavings were created at a 90-degree angle, producing small, thin curls ideal for igniting. I stabbed a rubber tire, then successfully created feather sticks, confirming the edge’s sharpness before the final challenge.

Advertisement — Continue Reading Below

Finale

Slicing a tomato is a true test for any knife. After days of use, it cut through a tomato effortlessly, with a secure lock and no blade play. It proved a real fighter, just like its namesake, Billy Waugh!

Advertisement — Continue Reading Below

Billy Waugh DEMO Knife Specs

| Overall Length | 9.13 inches/ 232 millimeters |

| Blade Length | 3.78 inches/ 96 millimeters |

| Steel | Böhler M390 |

| Rockwell Hardness | 60 |

| Blade Coating | Matte black PVD |

| Blade Thickness | .16″/ 4 millimeters |

| Handle Material | 3D Titanium |

| Carry | Tip-up |

| Weight | 6.80 ounces/ 193grams |

| Made in | Italy |

| MSRP | $495.00 |

For more information, check out STRAACK.