The Barrel

In Part 1 of this review, I mentioned that the Taurus Expedition’s hammer-forged barrel is the single most interesting aspect of this rifle. It’s not that other aspects of the Expedition rifle aren’t noteworthy. It’s quite the opposite. After all, its stock is well-thought-out and practical, its tri-lug Remington 700 pattern short-action is reliable and robust, and even the generic AICS pattern magazine hasn’t given me any real issues.

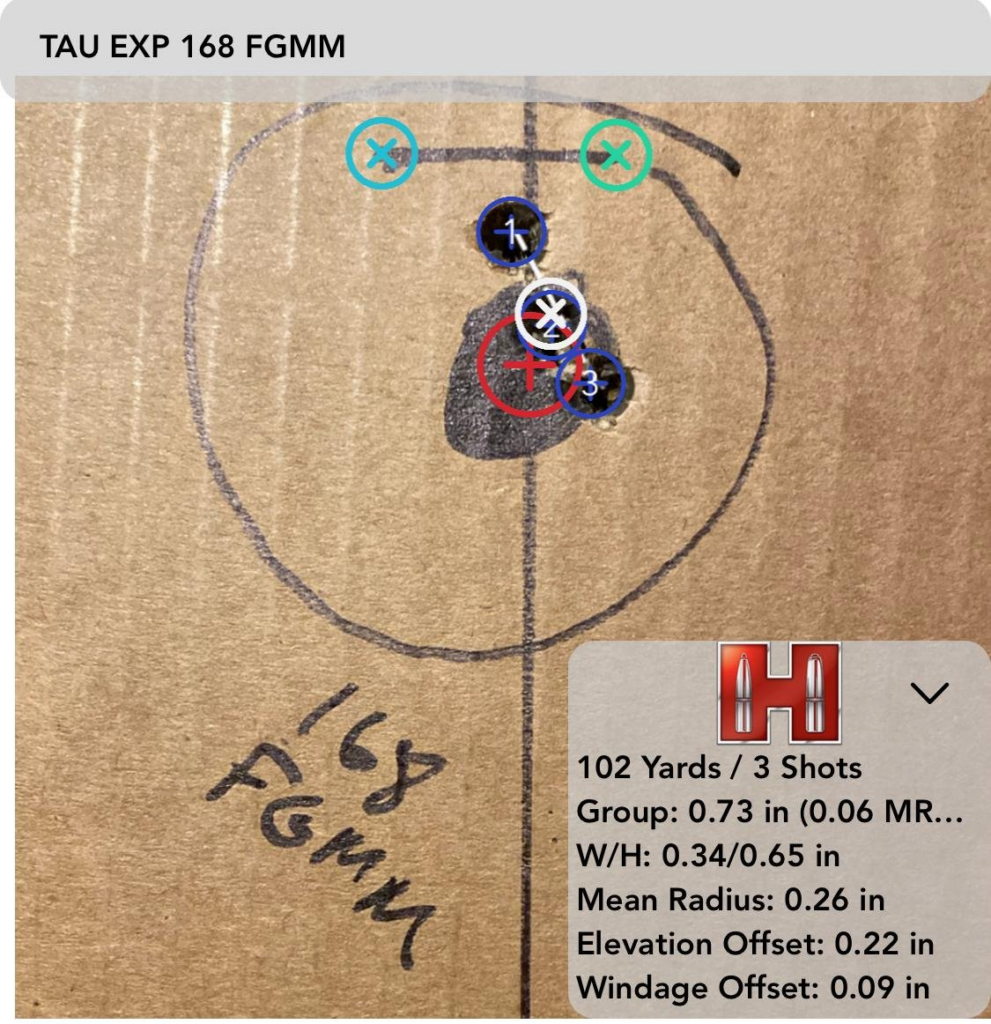

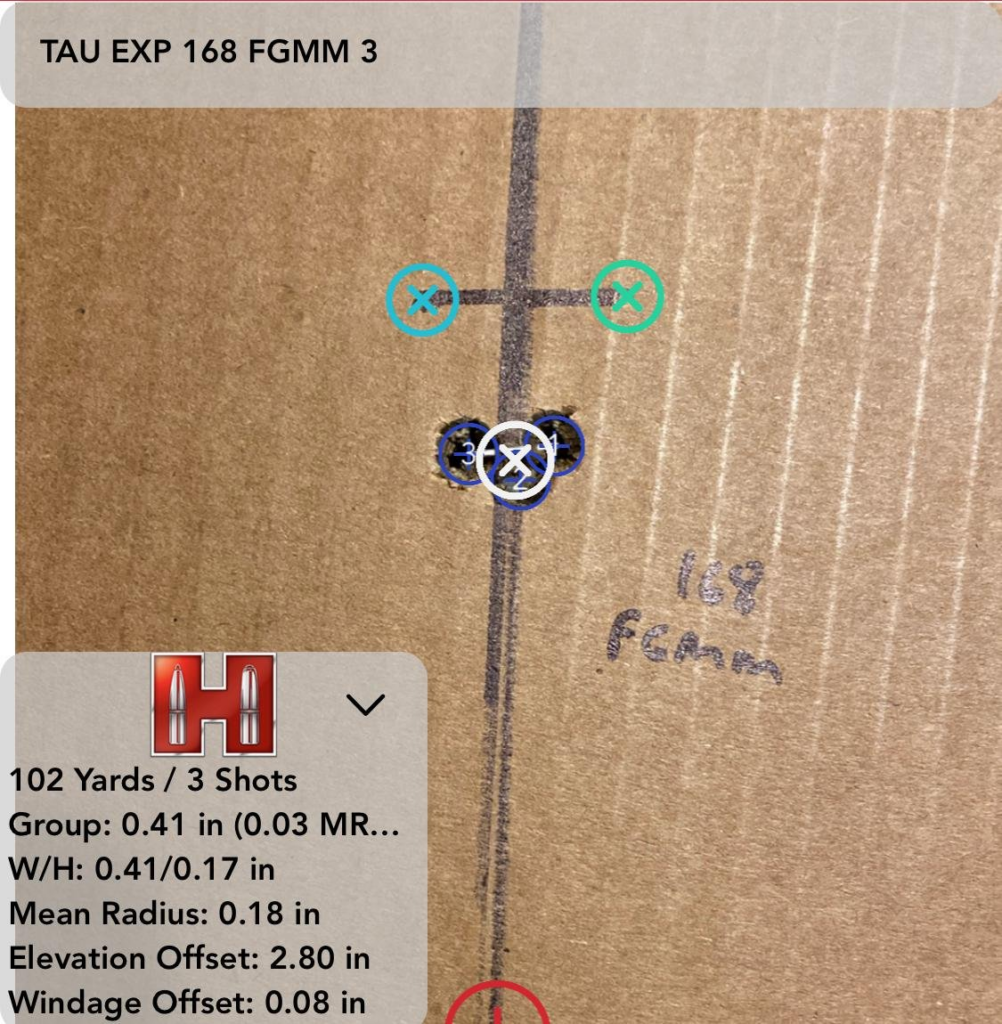

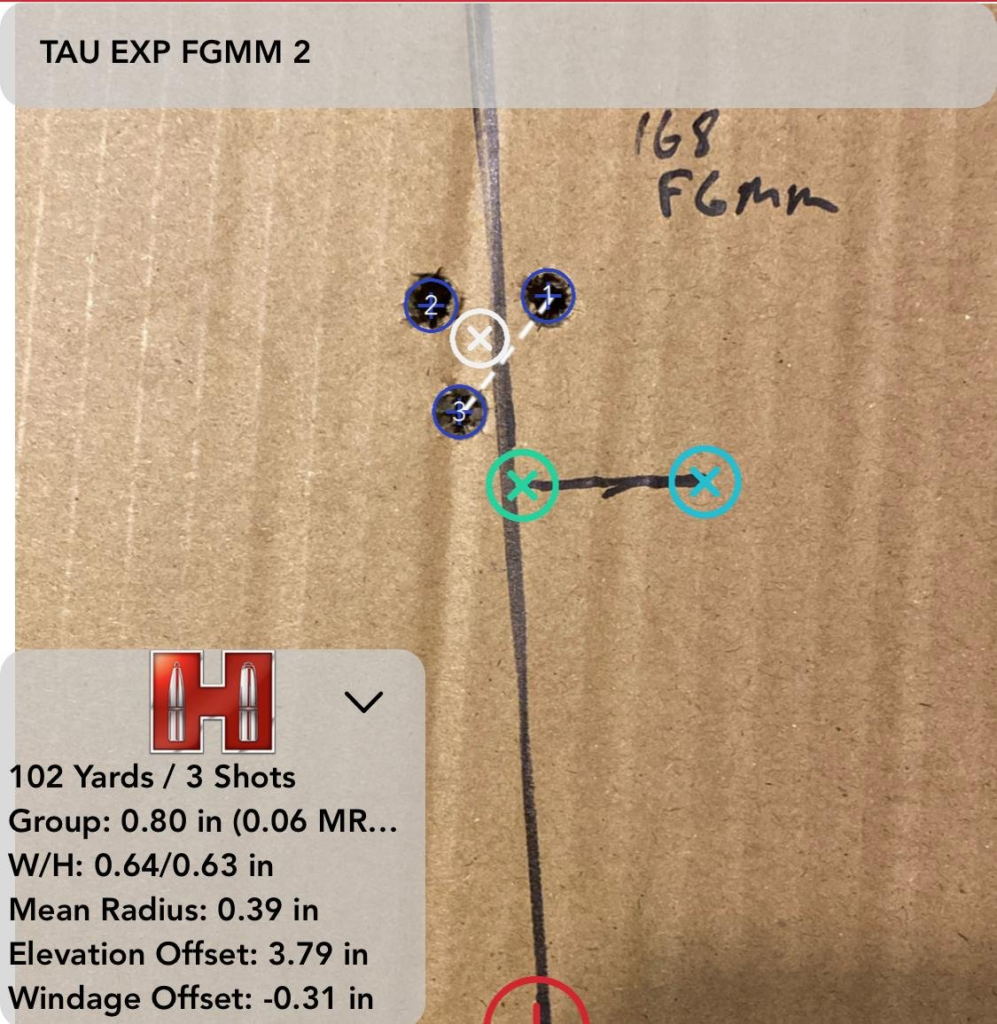

As a matter of fact, the Nightforce SHV 4-14×50 F1 C694 that I used from the start to conduct this review is currently zeroed for Federal’s legendary 168-grain Sierra Match king .308 Winchester cartridge. While reviewing the Nightforce SHV C694 rifle scope itself and checking the scope’s correction factor, I casually printed three separate sub-MOA 3-round groups with this Taurus rifle.

3-round groups aren’t without controversy. However, the fact that I managed to do it three different times with nothing more than a front and a rear bag for support with an otherwise stock rifle is attention-grabbing. From that moment onward, this rifle locked in my respect.

Taurus’ claim about this being a sub-MOA rifle isn’t unfounded. I’ll concede I used match ammo, not hunting ammo. The goal now is to find another .308 Winchester cartridge suitable for hunting and ethical harvesting of game that ballistically emulates the 168-grain Federal Gold Medal Match cartridge.

Evidence Of Work-Hardening

Work-hardening is a technical term in reference to metalworking. After a “cold” piece of metal has been subject to some type of mechanical force like pounding, folding, rolling, or hammering, its molecular structure basically realigns itself to become harder after withstanding several instances of said external stress.

The cold hammer forging manufacturing process is a way that gunmakers not only deliberately rifle their barrels but also allows the finished product to reap the benefits of work-hardening.

Originating from Austria, hammer-forging barrel machines are extremely massive and very expensive. Compared to other barrel-making techniques, hammer forging isn’t as common as, say, something like button-rifling. But in Europe, many arms factories still enjoy using this method.

I’m drawn to the Taurus Expedition’s barrel because hammer forging is a fascinating manufacturing technique. In the case of this specific rifle, the evidence of work-hardening is incorporated to add visual flair to the final product. In other words, the barrel still possesses a series of slanted and spiraling impressions all over its external surface from breech to muzzle.

Generally, rifle barrels are honed in order to remove these marks, the by-product of the hammer forging process. Leaving the imprints of the hammer blows all over a barrel is not something regularly seen. These spirals are both eye-catching and give the rifle an old-world craftsman’s wrought vibe. They add a bit of a rustic element that thematically fits the Expedition’s outdoor adventure product aura.

Taurus even decorated the cardboard box this rifle ships in with topographical map lines and outlines of pine trees and mountains. It also stood out because Taurus packaging tends to be plain without any thematic elements.

The Taurus Expedition Barrel: Technical Details

The Taurus Expedition’s 18-inch barrel is manufactured from stainless steel and finished with a sturdy black DLC (diamond-like finish). It uses a conventional twist rate of 1:10, which strikes a balance in its ability to stabilize projectiles weighing between 150 and 200 grains. As a field gun, it has a light-medium contour, which gives it a tendency to heat up after 3 to 5 shots–not a problem for its intended use case.

With the Taurus Expedition designed from the ground up as a modern and feature-rich hunting rifle, its barrel’s muzzle is cut and threaded for industry-standard ⅝ x 24-inch threads—what most .30 caliber diameter silencers work off of.

One of the first things I did when I took the Expedition home from my FFL’s shop was to remove the barreled action from its stock to have a better look at the rifle and take some pictures, some of which I’ve already shared in Part 1 of this review. After this photoshoot, I put the rifle back together while making sure the action screws were torqued correctly.

Given how my specimen’s barreled action sits in its stock, the barrel is generally free-floated, save for a very minuscule amount of plastic stock material that’s making slight contact with the wider left-side outer part of the barrel near the chamber area.

While I’ve taken a few shots with the Taurus Expedition rifle to both familiarize myself with the rifle and to review the Nightforce SHV C694 scope, the upcoming Part 3 of this review will showcase a selection of different .308 Winchester cartridges that I’m shooting for record, along with their chrono data.

Continued In Part 3

For more information, please visit TaurusUSA.com.